Research Direction

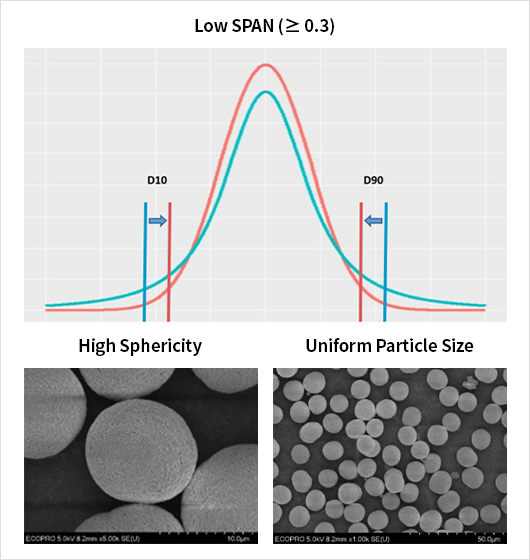

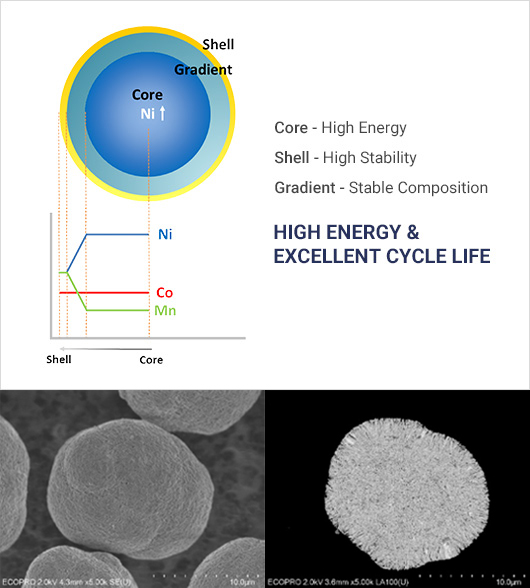

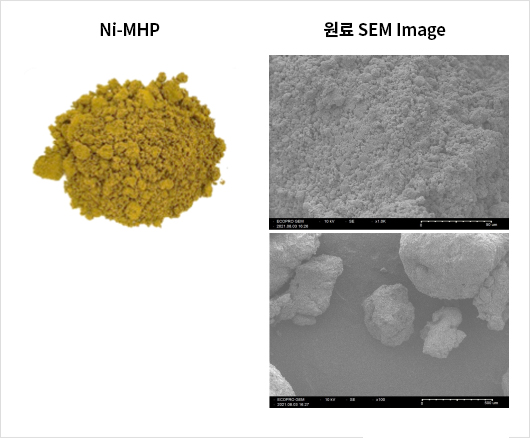

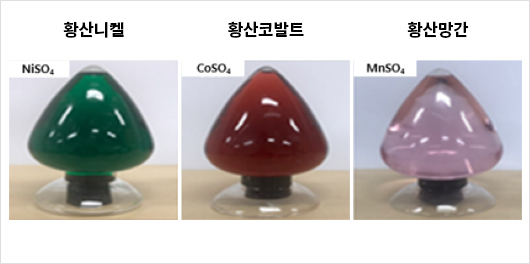

We are developing a complex mixed oxide precursor synthesis technology for cathode materials that satisfy various customer needs such as particle size control (2~17㎛), shape control (needle type, flake type), sphericality, and particle size distribution control.

Core Research Areas

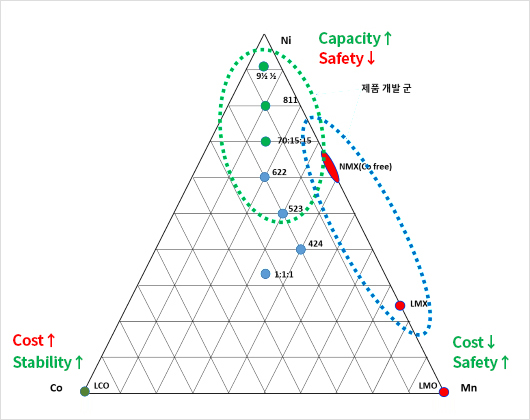

- Synthesis technology of High Nickel cathode active materials with Ni content of 94% or more starting from NCM523

- Synthesis process technology for various processes such as CSTR, Batch, and Cascade Reactor types

Reference Image